DIY Kit Flexible LED Screen Panel: From Concept to Reality

The advent of the DIY kit flexible LED screen panel has revolutionized the way we think about and interact with lighting and displays. These innovative kits allow enthusiasts and creators alike to assemble their flexible LED screens, which can be customized to fit a variety of spaces and purposes. From wrapping columns in luminous displays to creating curved screens for immersive video experiences, the potential applications are as limitless as your imagination. Opting to construct your flexible LED panel using a DIY kit not only provides the satisfaction of building something with your own hands but also offers significant advantages in terms of cost-effectiveness, customization, and learning. By choosing a DIY route, you gain a deeper understanding of the technology behind LED displays, empowering you to tailor every aspect of the project to your specific needs and creative vision.

What is the DIY Kit Flexible LED Screen Panel Technology

The Basics of Flexible LED Screens

Flexible LED screens are composed of light-emitting diodes (LEDs) embedded into a flexible substrate, allowing the screen to bend, fold, or roll while maintaining its display capabilities. This flexibility is achieved through the use of advanced materials and manufacturing processes that ensure the LEDs can move without breaking. Unlike traditional panels that are confined to flat, rigid surfaces, flexible LED screens can conform to various shapes and surfaces, opening up new avenues for installation and design.

One of the critical components of flexible LED screens is the substrate, the base material on which the LEDs are placed. Modern substrates are made from materials like flexible polymers or thin metal foils, which provide the necessary durability and flexibility. These substrates are then connected to flexible circuit boards, which power the LEDs and allow for the transmission of data to each diode, enabling the display of images and videos.

Advantages

Flexible LED screens offer several distinct advantages:

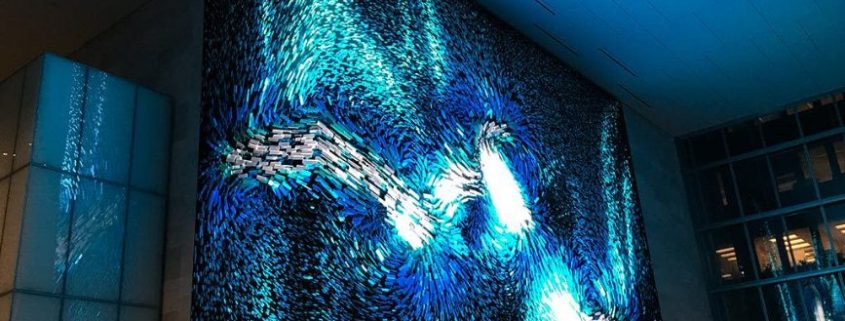

- Versatility in Design: The ability to bend and curve allows for creative installations that were previously impossible, such as wrapping around columns, creating immersive environments, or designing wearable technology.

- Lightweight and Thin: Flexible LED screens are significantly lighter and thinner than rigid panels, making them easier to install and less intrusive in various settings.

- Durability: Despite their flexibility, these screens are highly durable and resistant to impact, which reduces the risk of damage during installation or use.

- Energy Efficiency: Like all LED technology, flexible screens are energy-efficient, consuming less power than LCD or plasma screens while offering superior brightness and contrast.

Introduction to Programmable LED Displays and Their Functionalities

Programmable LED displays take the capabilities of flexible LED screens a step further by allowing users to control the content displayed dynamically. These screens can be programmed to show specific images, animations, or video content, which can be updated or changed according to the user’s needs. Programmable displays are particularly useful for advertising, dynamic art installations, or interactive environments where content needs to change regularly.

The core functionalities of programmable LED displays include:

- Custom Content Creation: Users can design and upload their content, from static images to full-motion videos, allowing for complete control over what is displayed.

- Dynamic Updating: Content can be changed or updated in real-time, either through direct programming or via network connections, enabling the display to react to events, user interactions, or other triggers.

- Interactive Capabilities: With the addition of sensors or input devices, programmable LED displays can become interactive, responding to user actions, environmental changes, or other inputs.

- Scheduling and Automation: Content can be scheduled to change at specific times or in response to particular conditions, allowing for automated operation without constant manual intervention.

Creating a DIY kit flexible LED screen panel that leverages the advantages of flexible LED technology and the dynamic capabilities of programmable displays allows for the creation of truly unique and impactful visual experiences. Whether for personal projects, commercial installations, or artistic endeavors, understanding these technological principles is the first step towards realizing the full potential of your DIY flexible LED screen panel.

Planning Your DIY Kit Flexible LED Screen Panel Project

Determining the Purpose

The first step in planning your DIY kit flexible LED screen panel project is to clearly define its purpose. The intended use of your LED screen will guide many of your subsequent decisions, including size, resolution, and even the type of LEDs you select. Are you creating an ambient lighting solution for your home theater? A dynamic backdrop for live performances? Or perhaps an engaging advertising display for commercial use? Each application comes with its unique set of requirements and challenges.

For instance, a screen intended for video playback will require a higher resolution to ensure clear image quality, while a display used for atmospheric lighting may focus more on color accuracy and dimming capabilities. Similarly, an outdoor installation must consider weather resistance and brightness levels to combat direct sunlight, unlike its indoor counterparts.

Deciding on the Size

Once the purpose of your flexible LED screen is defined, the next crucial step is determining its size. The size of your LED panel plays a significant role in both its impact and feasibility. Larger screens offer more space for detailed graphics and visibility from a distance but require more LEDs, power, and structural support, potentially increasing the complexity and cost of your project.

To decide on the appropriate size for your LED screen, consider the following:

- Viewing Distance: The intended viewing distance helps determine the necessary size and pixel density (PPI or pixels per inch) of your screen. Screens viewed from farther away can have lower PPI while maintaining image clarity.

- Space Limitations: Assess the physical space where the screen will be installed. Measurements of the area will provide a maximum size limit, ensuring the screen fits comfortably within its environment.

- Aspect Ratio: Depending on your content, you may opt for a standard 16:9 aspect ratio for videos or a custom ratio for unique display configurations. The aspect ratio will affect both the dimensions and layout of your LED screen.

- Flexibility Needs: The beauty of working with flexible LED panels is the ability to create curved or non-linear displays. Consider how the flexibility of the LED screen can be used to enhance your project, whether it wraps around corners, conforms to irregular shapes, or adds dimensionality to flat surfaces.

- Modularity for Future Expansion: Planning for modularity from the outset offers the flexibility to expand or alter your screen in the future. Design your initial project with expansion in mind by choosing modular components that can be easily reconfigured or added to. This foresight allows your LED screen to evolve alongside your changing needs or creative ambitions.

The planning stage of your DIY kit flexible LED screen panel project lays the foundation for its success. By carefully considering the purpose and size of your screen, you ensure that the final product is not only a reflection of your vision but also a practical and impactful addition to its intended space. This thoughtful approach to planning empowers you to move forward confidently, with a clear roadmap guiding your selections of materials, design considerations, and construction techniques.

Components of a DIY Kit Flexible LED Screen Panel

Creating a flexible LED screen panel from a DIY kit involves assembling various components that work together to produce a versatile and dynamic display. Here’s a detailed list of the essential parts you’ll need to bring your project to life:

- Flexible LED Strips: The core of your screen, these strips come in various types, including RGB, RGBW, and single-color LEDs. They can bend to fit curved surfaces and are available in different brightness levels and pixel densities.

- Flexible PCB (Printed Circuit Board): A PCB that can bend and flex is essential for attaching your LED strips and other components if you’re building the panel from scratch.

- Microcontroller or LED Controller: Acts as the brain of your panel, allowing you to program and control the LEDs. Popular choices include Arduino for its flexibility and Raspberry Pi for more complex programming needs.

- Power Supply: Ensure you have a power supply with the correct voltage and amperage to safely power your LED strips without overheating.

- Diffuser Material: To create an even light distribution and soften the brightness of the LEDs, a flexible diffuser material, such as frosted silicone or thin acrylic, is necessary.

- Connecting Cables and Wires: Essential for connecting the LED strips to the power supply and controller. Flexibility is key to maintaining the screen’s ability to bend.

- Soldering Iron and Supplies: For custom kits or adding additional components, having a soldering iron and the appropriate soldering supplies is necessary for making secure electrical connections.

- Adhesive or Mounting Solution: Depending on where and how you plan to install your flexible LED screen, you may need strong adhesives or a custom mounting solution that allows for flexibility.

- Programming Software: Depending on your controller, you may need specific software to program your display. Many controllers have compatible software available for download.

Recommendations for Sourcing Quality Components

When assembling a DIY kit flexible LED screen panel, the quality of components significantly impacts the performance and durability of the final product. Here are some recommendations for sourcing these components:

- Flexible LED Strips: Look for reputable brands that offer LED strips with high brightness, color accuracy, and longevity. Brands like Adafruit and SparkFun are known for their quality and offer a range of options suitable for various projects.

- Microcontrollers and LED Controllers: Purchase from reputable electronics suppliers or directly from the manufacturers like Arduino.cc or RaspberryPi.org to ensure you’re getting authentic and reliable components.

- Power Supplies: Opt for power supplies from established manufacturers with safety certifications. Avoid generic or unbranded power supplies, as these can be unreliable and unsafe.

- Diffuser Materials: Specialty plastics suppliers or online marketplaces like Amazon offer diffuser materials suited for LED applications. Look for materials that offer a good balance between light diffusion and transmission.

- Amazon: A convenient source for many components, Amazon offers a wide range of flexible LED strips, controllers, power supplies, and diffuser materials. Be sure to read reviews and check seller ratings to ensure you’re purchasing high-quality components.

- Electronics Hobbyist Stores: Stores like Adafruit, SparkFun, and Digi-Key cater to electronics enthusiasts and DIYers, offering a curated selection of components ideal for building a flexible LED screen panel.

- Specialty LED Suppliers: For high-end or specialized LED strips (such as those with ultra-high pixel densities or unique color capabilities), look to suppliers that cater to professional lighting designers and installers.

By carefully selecting each component and sourcing from reputable suppliers, you can ensure that your DIY kit flexible LED screen panel not only meets your expectations but also stands the test of time. Whether you’re creating an eye-catching display for a special event, enhancing your home with dynamic lighting, or experimenting with interactive installations, the right components are the foundation of a successful project.

Assemble the DIY Kit Flexible LED Screen Panel Frame

Understanding the Requirements

The frame for a flexible LED screen needs to satisfy several key criteria:

- Lightweight: Ensuring ease of installation and minimal stress on the supporting structure.

- Durability: Capable of holding the LED modules securely over time, without warping or degrading.

- Flexibility: Allowing the LED panel to curve or bend as needed, opening up creative display possibilities.

- Modularity: Facilitating easy expansion or reconfiguration to adapt to changing needs or environments.

Materials Selection

Choosing the right materials is critical to meeting these requirements. Aluminum extrusions are often preferred for their strength-to-weight ratio, corrosion resistance, and thermal conductivity, which can help dissipate heat from the LEDs. For frames that require significant bending or curving, materials with higher flexibility, such as certain plastics or composite materials, may be used in conjunction with or instead of aluminum.

Step-by-Step Construction

- Design Planning: Begin with a detailed sketch or CAD drawing of the frame, incorporating dimensions, locations for mounting points, and areas where flexibility is required. This plan will serve as your blueprint throughout the construction process.

- Cutting Materials: Once you’ve selected your materials, cut them to size according to your design plans. Precision is key to ensuring all pieces fit together perfectly. Tools like a miter saw (for aluminum) or a fine-toothed saw (for plastics) can provide clean, accurate cuts.

- Assembling the Frame: Join the cut pieces to form the basic shape of your frame. For aluminum extrusions, specialized connectors can be used to secure the pieces without welding, which maintains the material’s integrity and allows for disassembly if needed. If using more flexible materials, adhesives or mechanical fasteners designed for the specific material will be necessary.

- Incorporating Flexibility: For areas of the frame that need to bend or flex, consider using flexible joints or designing the frame in segments that allow for movement. Ensure that these flexible points are strong enough to support the weight of the LED modules and any additional stress from bending.

- Testing the Frame: Before mounting the LED modules, test the frame’s strength and flexibility. Apply gentle pressure to ensure it can support the intended weight and bend without deforming or breaking. Adjustments should be made as necessary to reinforce any areas that feel weak or unstable.

- Preparing for LED Installation: Attach any mounting brackets or adhesive strips that will hold the LED modules in place. If the frame will be exposed to outdoor elements, apply a protective coating to prevent corrosion or material degradation.

- Modularity for Expansion: Design the frame with modularity in mind. Use connectors that allow for easy removal or addition of segments. This foresight will enable you to expand the size of your LED screen or reconfigure its shape with minimal effort in the future.

Tips for Successful Frame Construction

- Choose materials and connectors that are rated for both indoor and outdoor use if there’s any chance your screen may be exposed to the elements.

- Consider the weight of your entire assembly, including the frame, LED modules, and any protective coverings or diffusers. Ensure the supporting structure (wall, ceiling, etc.) can safely bear this weight.

- Plan for heat dissipation. LED modules generate heat, so designing the frame to facilitate airflow can help extend the life of your LEDs.

By following these detailed instructions and considerations, you can construct a frame that perfectly suits your DIY kit flexible LED screen panel. This frame will not only provide a secure foundation for your LED modules but also offer the flexibility to bring your creative visions to life. Whether for home entertainment, commercial advertising, or artistic expression, your LED screen will stand as a testament to the possibilities afforded by thoughtful design and skilled craftsmanship.

DIY Kit Flexible LED Screen Panel: Install LED Strips and Modules

The installation process is a delicate balance between technical precision and creative vision, requiring careful planning and execution. Follow this step-by-step guide to ensure that your LED strips and modular panels are installed correctly and safely on your flexible frame.

Preparing Your Workspace and Materials

- Gather Your Materials: Ensure you have all necessary components, including LED strips, flexible PCB (if using individual LEDs), a flexible frame or backing material, soldering iron, and connectors.

- Workspace Preparation: Set up a clean, well-lit workspace with enough room to lay out your frame and materials. A static-free mat is recommended to protect sensitive electronic components.

Arranging LED Strips and Modules

- Planning Your Layout: Before attaching anything, plan your LED strip arrangement. Consider the panel’s final use to determine the best layout for even light distribution and desired visual effects. For artistic displays, you might want an irregular, dynamic pattern. For lighting purposes, evenly spaced strips might be best.

- Cutting LED Strips: If your project requires specific lengths, cut your LED strips at the designated cut marks to fit your layout plan. Be precise to avoid damaging the strips.

- Testing LED Strips: Before installation, connect each strip or module to a power source to ensure they’re working correctly. This step can save time and frustration later.

Attaching LED Strips to the Frame

- Securing LED Strips: Begin attaching your LED strips to the flexible frame or backing material. If using adhesive-backed strips, carefully peel off the backing and press the strip onto the material. For additional security, especially on more flexible or curved surfaces, consider using clear, flexible glue or silicone.

- Wiring and Connections: Solder connections between strips if needed, paying close attention to polarity to ensure consistent power flow. Use flexible wires to accommodate the panel’s bending and flexing capabilities.

- Connecting to the Controller and Power Supply: Attach your LED strips or modules to the controller, again ensuring proper polarity. Connect the controller to the power supply, and arrange any additional circuitry required for your project.

- Final Testing: Once everything is connected, test the panel again to check for any issues with connections, lighting consistency, or controller functionality.

Optimizing Lighting Distribution and Visual Effect

- Adjusting for Even Light Distribution: If you notice any uneven brightness or color across your panel, adjust the spacing of your LED strips or add more strips in dimmer areas. A diffuser layer can also help soften and even out the light.

- Programming for Desired Visual Effects: Utilize the programming capabilities of your controller to customize lighting patterns, sequences, or responses to input, enhancing the dynamic nature of your display.

- Installation and Mounting: Finally, install your flexible LED panel in its designated location. Ensure it’s securely mounted but also retains its flexibility if needed for the project’s design intent.

Building and installing a DIY kit flexible LED screen panel is a process that combines technical skills with creative design. By carefully selecting your components, planning your layout, and following these installation steps, you can create a flexible LED display that not only meets your functional requirements but also captures your artistic vision. Whether used for ambient home lighting, dynamic signage, or interactive art, your DIY flexible LED screen panel stands as a testament to the power of personal fabrication and the endless possibilities of LED technology.

Wiring and Electronics Setup for Your DIY Kit Flexible LED Screen Panel

Preparing for Wiring

Before you start, it’s essential to have a clear wiring diagram based on your LED screen’s design. This diagram should detail the connections between the LED modules, power supply, and any controllers or sensors you plan to include. Having this roadmap will simplify the installation process and help prevent errors.

Tools and Materials Needed:

- Wire strippers and cutters

- Soldering iron and solder (for making durable connections)

- Heat shrink tubing (to insulate and protect connections)

- Multimeter (for testing connections)

- Quality electrical wires (appropriate gauge based on current requirements)

Connecting LED Modules

- Identify Positive and Negative Leads: Start by identifying the positive (+) and negative (-) leads on your LED modules. These will need to be correctly matched to the power supply’s output to ensure proper operation.

- Series vs. Parallel Configuration: Decide whether your LED modules will be connected in series or parallel. A parallel configuration is often recommended for LED panels to ensure uniform brightness and to prevent a single failed module from affecting the entire array.

- Making Connections: Use the electrical wires to connect the LED modules according to your wiring diagram. In a parallel setup, all positive leads connect to the power supply’s positive output, and all negative leads to the negative output.

- Soldering for Durability: Where possible, solder the connections between wires and LED modules to ensure they are secure and offer low resistance. Cover each soldered connection with heat shrink tubing to protect and insulate it.

Ensuring a Reliable Power Supply

- Calculate Total Power Requirements: Add up the power requirements of all your LED modules to determine the total current draw. Select a power supply that can provide at least 20% more current than your total calculated need to ensure reliability without overheating.

- Voltage Considerations: Ensure the power supply’s output voltage matches the requirements of your LED modules. Using a power supply with a higher voltage than your LED modules are rated for can lead to damage.

- Connect Power Supply: Once all LED modules are correctly wired, connect the power supply to the system. Before turning it on, double-check all connections using your multimeter to ensure there are no shorts or incorrect connections.

Integrating Controllers for Programmable Displays

- Selecting a Controller: Choose a controller that matches the capabilities you want for your display. This could be a simple on/off switch, a dimmer, a color-changing controller, or a microcontroller for more complex programmable effects.

- Wiring the Controller: Integrate the controller into your circuit according to the manufacturer’s instructions. Typically, this means connecting it between the power supply and the LED modules.

- Programming the Controller: For microcontroller-based setups, program the controller with the desired sequences, effects, or responses. This can include anything from simple color changes to complex patterns or even interactive responses triggered by sensors.

- Testing Interactivity: If your display is designed to be interactive, test the functionality thoroughly. Ensure that sensors correctly trigger the desired responses in the LED display.

Final Checks and Testing

Once everything is wired and set up, conduct a comprehensive test of your LED screen. Check for consistent brightness across all modules, proper operation of the controller, and responsiveness to any interactive elements. Use your multimeter to verify that current draw is within safe limits.

Setting up the wiring and electronics for your DIY kit flexible LED screen panel is a meticulous process that rewards careful planning and precision. By ensuring that your LED modules are correctly connected and powered and by integrating a controller that opens up possibilities for programmable and interactive displays, you bring your flexible LED screen to life. This guide aims to equip you with the knowledge to navigate the complexities of wiring and electronics setup, ensuring that your DIY project not only works as envisioned but also stands as a testament to your technical skill and creativity.

FAQs about DIY Kit Flexible LED Screen Panel

Creating a flexible LED panel involves using LED strips that can bend and flex, allowing you to mount them on various surfaces or create shapes and designs that a rigid panel cannot achieve. Here’s a step-by-step guide:

Materials: You will need flexible LED strips, a flexible backing material (such as a thin, bendable plastic sheet or fabric), a power supply, and a controller if you want the panel to be programmable.

Design Your Panel: Determine the size and shape of your LED panel. Sketch your design, noting where each strip of LEDs will be placed.

Attach LED Strips: Affix the LED strips to your backing material using their adhesive backing or with a suitable glue that won’t damage the strips or the backing. Ensure the strips are evenly spaced and securely attached.

Wiring: Solder connections between the LED strips if they need to be linked together. Make sure to maintain the correct polarity throughout the panel.

Power and Control: Connect the LED strips to the power supply and the controller. If you’re making a simple panel without programmability, you might only need a power supply suitable for the voltage and current requirements of your LED strips.

Testing: Test your panel to ensure all LEDs light up and there are no short circuits.

Making a LED screen from scratch requires assembling individual LEDs or pre-made LED modules into a display, connecting them to a control system, and programming the display to show content. Here’s a simplified process:

Gather Materials: Collect LED modules, a suitable control system (like an Arduino or Raspberry Pi for smaller projects, or specialized LED controllers for larger screens), power supplies, and cables.

Design the Screen Layout: Plan how large your screen will be and how the LED modules will be arranged. Consider the resolution you want to achieve.

Assemble the Modules: Mount the LED modules onto a frame or panel in your chosen layout. Ensure they are securely attached and properly aligned.

Wiring: Connect the modules together and to the control system and power supply, following the requirements for voltage and current.

Programming: Use software compatible with your control system to program the display. This could range from simple scrolling text to complex images or videos.

Testing: Power up your screen and test the display for any issues.

Creating a programmable LED display board involves integrating LEDs with a microcontroller or computer that can dynamically change the displayed content. Here’s how:

Select Components: Choose your LEDs or LED matrix, a microcontroller (Arduino is a popular choice for beginners), and any other necessary components (resistors, capacitors, etc.).

Design the Display: Plan the layout and wiring of your LEDs. For a matrix, you might use a grid layout.

Build the Circuit: Assemble your LEDs on a breadboard or PCB, wiring them to the microcontroller according to your design.

Program the Microcontroller: Write or modify a program that controls the LEDs. The complexity of the program will depend on the content you wish to display.

Test and Troubleshoot: Upload your program to the microcontroller and test the display. Troubleshoot any issues that arise.

A flexible LED screen is a type of display made with LEDs that are mounted on a flexible substrate, allowing the screen to bend, fold, or twist without breaking. This flexibility opens up new possibilities for installation and design, allowing for curved surfaces, wrapped columns, or even wearable displays. Flexible LED screens are used in various applications, from innovative architectural designs to dynamic stage backgrounds and interactive art installations. The technology behind these screens typically involves either small, individually mounted LEDs on a flexible material or LED strips that are affixed to or embedded within a bendable surface.

As the founder and leading expert of Shine LED Display, I, Ponsent Wu, bring over a decade of specialized experience in the LED display industry. My brand is dedicated to providing top-tier LED display solutions, ranging from high-definition screens for commercial use to customized installations for various events and projects. At Shine LED Display, we pride ourselves on offering a comprehensive service that includes design, configuration, installation, and expert troubleshooting. Whether you’re looking to enhance your business with a vibrant advertising display, create an unforgettable event with dynamic visuals, or have specific questions and needs regarding LED technology, I am here to ensure your vision is brilliantly realized. For any inquiries or to discuss your LED display needs, don’t hesitate to contact me at any time. Your satisfaction is the beacon that guides us at Shine LED Display.